Reveal hidden profits in the indirect commodity groups

- Reveal hidden profits in the indirect commodity groups

- Duet of expertise and buyer’s gene

- Regular sourcing and tendering: Customer requirements and suppliers change

- Standardization of products

- Learning by Doing: Colleagues & Coaches on a temporary basis

Read in this article how to make visible and leverage high hidden savings in indirect commodity groups.

Experience shows that companies usually focus their purchasing activities on direct commodity groups. These classically include raw materials that are used to manufacture the company’s own product portfolio. Within the retail industry, these would be the classic trade goods.

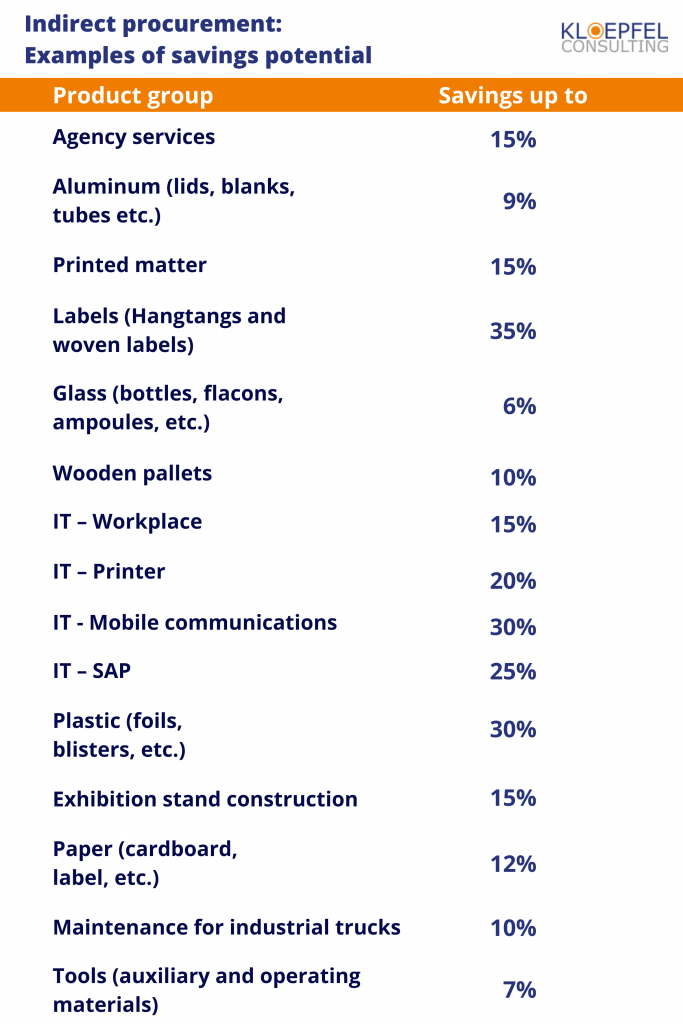

Indirect commodity groups, on the other hand, are all goods and services that do not flow directly into the products but are necessary for the smooth continuation of business operations. Often, the purchasing volumes for indirect commodity groups are significantly lower, which means that these tend to take a back seat in the overall view.

Indirect product groups often only come into a company’s focus when massive price increases come into play. For example, this has recently been the case with energy or paper.

Not least because of maverick buying, it is worth examining the extent to which accounts payable can be bundled and thus volume effects generated.

Duet of expertise and buyer gene

Another reason for the high savings potential in the indirect commodity groups is that the specialist departments are usually familiar with the specifications and performance of the products and services to be procured but have no purchasing and negotiation expertise. Some companies therefore already instruct their specialist departments that purchasing is to be integrated into the procurement process, but this often only happens at a late stage. It is not uncommon for a decision to have already been made in favor of a supplier, or for there to be insufficient time for the purchasing department to carry out a detailed supplier search and then put the products and services to be procured out to tender on the market in their entirety.

The employees of Kloepfel Consulting combine a wide range of technical expertise with a strong buyer’s gene and are thus able to support companies in their purchasing activities quickly and with the help of appropriate negotiation levers.

Regular sourcing and tenders: Customer requirements and suppliers change

In addition, it often makes sense to repeat an extensive sourcing and a holistic tender at regular intervals. For example, the company’s requirements may have changed in the meantime (in terms of specifications or quantities required), so that other suppliers may be a better fit. It is also possible that alternative suppliers have renewed their machinery and can therefore produce the specific requirements at a reduced price.

Standardization of products

The lack of standardization of products also conceals potential savings in indirect purchasing. We therefore recommend regularly reviewing the specifications of the required products to determine the extent to which minor adjustments can be made to the standard product portfolio of various suppliers.

Learning by Doing: Colleagues & Coaches on a temporary basis

Our consultants go to the companies as temporary colleagues and coaches, so that the buyers can learn a lot about the relevant product groups and see how we prepare and conduct negotiations, for example. With the expertise and negotiation know-how they gain, they can subsequently tender and negotiate prices and conditions much better in coordination with the specialist departments.

Contact:

Kloepfel Group

Christopher Willson

Pempelforter Str. 50 | 40211 Duesseldorf

Tel.: 0211 941 984 33 | Mail: rendite@kloepfel-consulting.com