Interview partner:

Source: WITTENSTEIN SE

Before the Kloepfel project, did you carry out an analysis of the potential savings?

Sven Siegl: Yes, and that was a very exciting topic. We were also convinced by the preliminary work and the team with its in-depth know-how. The presentation of the results of the potential analysis was equally convincing.

Michael Löser: I felt the same way. Even during the potential analysis, it became clear how much we as a company, and especially our purchasing team, could benefit from the expertise there. I spoke to some employees and asked them whether we should carry out the project. They all agreed: “Yes, we will do it. It will help us and move us forward.” Apart from the commercial savings, Kloepfel’s methodology and expertise were key factors for us. That’s what led us to start the project.

What were the goals of the project?

Sven Siegl: Of course, it was of great importance to save costs. But apart from that, we also wanted to draw a comparison with other companies. The focus was on benchmarking and confirming or optimizing our strategy. We also wanted to learn from the project in order to expand our toolbox.

Which product groups were in process?

Sven Siegl: The analysis led to the focus on logistics and packaging materials. We wanted to take a comprehensive look at our logistics – from transports, special deliveries and express services to pallets. In addition, the focus was on marketing, IT, maintenance cleaning, auxiliary and operating materials, tools, and maintenance of forklift trucks.

How satisfied were you with the project result?

Michael Löser: The savings, especially in the area of transports, were absolutely satisfactory and far exceeded our expectations. But what impressed us even more was the human level and sensitivity that Kloepfel showed. They knew exactly in which areas things could get difficult and where they had to proceed with more caution. In addition, Kloepfel did a good job of involving WITTENSTEIN SE employees and coordinating communication with suppliers.

I was initially concerned that we might have a negative impact in some places, but that was not the case at all, quite the opposite.

The fact that we won over the departments, that we were able to improve quality and that we now maintain a close relationship with the specialist departments was for me – in addition to the cost savings – the real result of the project.

What were the biggest challenges of the project?

Sven Siegl: In areas where the specialist departments were not used to purchasing actively supporting them in recent years, we certainly had some challenges at the start of the project. During the project, we also had a very tight schedule. The offers came back and had to be evaluated, talks were scheduled, negotiations were conducted, and we had to adjust the strategy accordingly and react to new circumstances. In cooperation with Kloepfel, we were able to successfully manage these challenges.

Another aspect that I would like to emphasize as a manager is the fact that we temporarily worked with Kloepfel with additional “temporary colleagues and coaches”. In terms of management, I had the feeling that our department had suddenly doubled in size and that significantly more decisions had to be made.

Source: WITTENSTEIN SE

How sustainable is the success of the project?

Michael Löser: It wasn’t just about savings. Rather, care was taken not to jeopardize existing supplier relationships. Sustainable success also includes the fact that our purchasing team learned a great deal. Both in terms of tools and methods as well as the preparation, execution and timely implementation of the measures.

Another important aspect of the project was the joint development of the results. We were present at supplier meetings, had common contact persons and communication was consistent. This enables us to continue to talk to suppliers on a good and professional basis and to apply what we have learned.

What tools and measures did the consultants use on site?

Sven Siegl: We used various levers in the different product groups, such as strategic negotiations and tenders. We tested the e-auction topic and it worked well.

Otherwise, I think it is important to reflect on the project afterwards in order to learn from it. In addition, Purchasing can continue to use tender documents from the project, for example, across all sites.

Michael Löser: The tender document for cleaning services is a good example of these tender documents. In the past, there were often discussions about whether something was cleaned properly or not. Now we have once taken the trouble to write down the requirements for the cleaning service provider and get both much better bids and results. We have done the same for transportation. These are methodologies we will continue to use.

At the beginning of consulting projects, companies usually fear an additional workload. How did you feel about that?

Sven Siegl: We were aware from the start that the project would involve an additional burden over a period of time. What made it easier was the fact that we had a positive attitude and support from the employees right from the start. It was definitely a challenging time, but no one complained about the extra workload.

How did you manage to get the employees on board for the project?

Sven Siegl: The employees were closely involved right from the start and immediately got along with the Kloepfel team. In addition, the measures were well justified, so that everything was comprehensible to them. Together with Kloepfel, we managed very well to ensure that no one thought someone was coming who knew everything better. Rather, it was a mutual complementing.

Source: WITTENSTEIN SE

How have the suppliers reacted to the project?

Michael Löser: It is remarkable that we have succeeded in achieving very good results on the one hand and at the same time maintaining the relationships with the suppliers. Often, such issues come at the expense of established structures, which one accepts as collateral damage. But that was not the case here.

Sven Siegl: I can only remember one case in which the interlocutor reacted defensively and emotionally. But that was the only negative example.

What is the longer-term vision for purchasing?

Michael Löser: The long-term vision for Purchasing is to maintain existing partnerships and to make the implemented changes sustainable without neglecting competitiveness. In the next step, we will integrate additional sites and regions into the various merchandise group strategies. The course for this has already been set. To this end, we will continue to use the methods and tools from Kloepfel that we learned during the project.

What is your conclusion of the project?

Sven Siegl: In summary, I can say that this project was a complete success in many aspects. Whether it be from the result, the cooperation, the information we got about the market, the tools and methods we acquired and last but not least the deep expertise of Kloepfel. We can recommend the “temporary colleagues and coaches” of Kloepfel Consulting to every company.

Brief profile

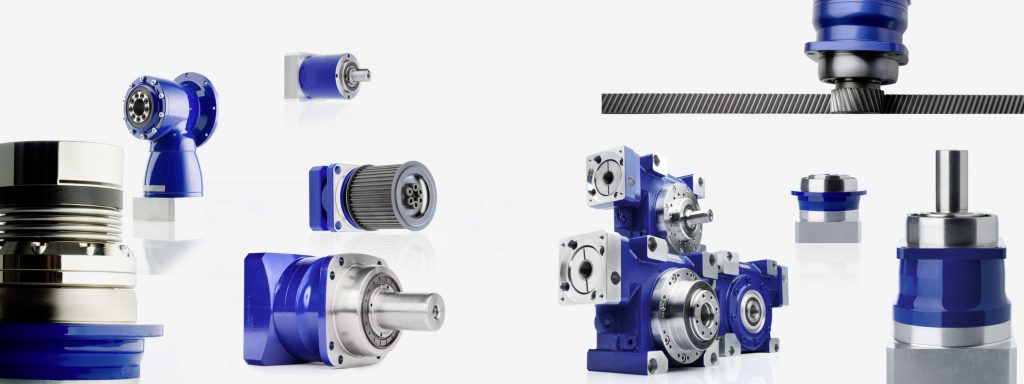

WITTENSTEIN – being one with the future

With around 2,800 employees worldwide and sales of €461 million in fiscal 2021/22, WITTENSTEIN SE stands for innovation, precision and excellence in the world of cybertronic motion, both nationally and internationally. The Group possesses superior expertise in mastering and further developing all relevant technologies in mechatronic drive engineering and comprises six innovative Business Units. High-precision servo drives and linear systems, servo systems and motors, and cybertronic drive systems, among others, are developed, produced, and marketed for mechanical and plant engineering, aerospace, and oil and gas exploration. Nanotechnology and software components round off the portfolio. The WITTENSTEIN Group is represented at 25 locations and in more than 45 countries in all key technology and sales markets.

Contact:

Kloepfel Group

Damir Berberovic

Tel.: 0211 941 984 33 | Mail: rendite@kloepfel-consulting.com