How long does order processing take in our company – not really, or does it?

In our consulting practice, we repeatedly find that companies lack transparency regarding how the ordering process is conducted and which departments are involved. Often, there is only a feeling that it takes too long.

Especially in today’s times, it is urgently necessary to engage with employees and processes to be able to successfully compete. Here are some thoughts.

In current surveys among entrepreneurs, two main challenges are usually mentioned – cost pressure due to market competition and a shortage of labor. Against this backdrop, it is worthwhile to consider which activities are value-adding for the customer and simultaneously meaningful and necessary for the employees.

Due to the increasingly severe labor shortage in the coming years, companies will be forced to restructure so that fewer employees in the departments can achieve more without burning out. This naturally applies to all departments involved in the procurement process as well.

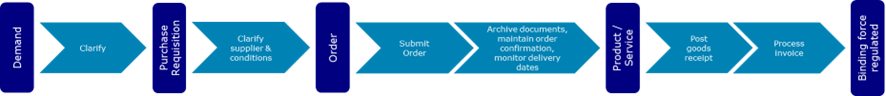

When considering a generic procurement process, it quickly becomes clear that it likely involves more than just purchasing.

In our analysis, the process begins with a department already having a concrete idea of what needs to be procured and ends with payment of the invoice.

We can now roughly divide this process into 3 phases

Ordering Phase

Check demand, clarify conditions, create order

Operational Phase

Maintaining order confirmations, tracking deadlines, booking goods receipt

Invoice processing

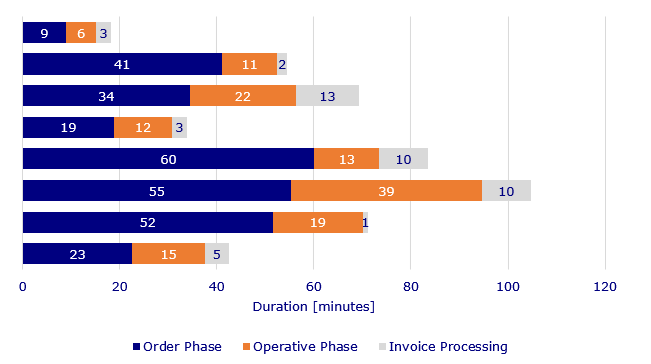

The following data is based on surveys we recently conducted among various companies in the metal industry in the DACH region regarding orders in the maintenance sector. Catalog solutions and electronic connections to suppliers were not used.

Figure 2 provides an overview of the time required for the complete order processing. Depending on the maturity level of the company, the range varies from 18 to 104 minutes per order.

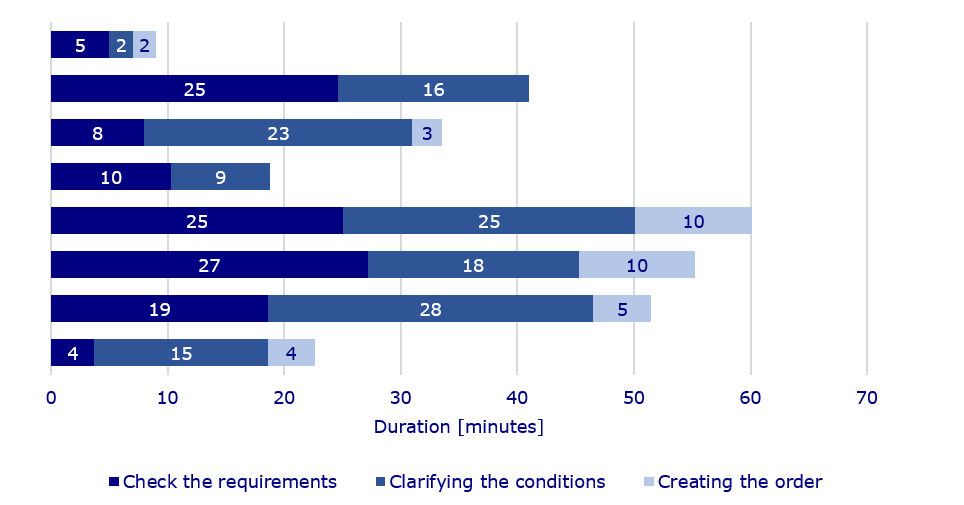

Ordering Phase

We frequently hear from purchasing departments that the information from the departments is incomplete and further clarifications are necessary for an inquiry.

The inquiry itself varies in quality and standardization.

The order is generally created and submitted quite well – but here too, we often see potential for improvement.

Figure 3 shows the time required for the individual process steps of the ordering phase per company.

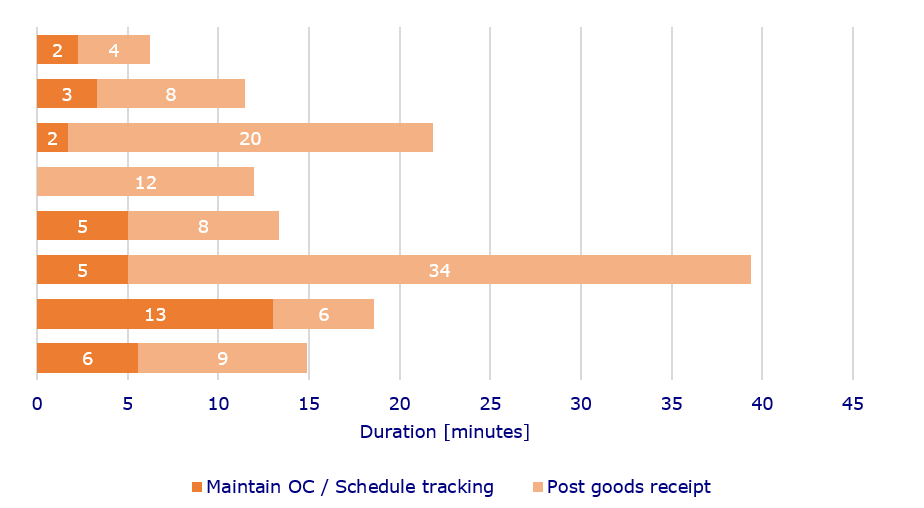

Operational Activities

Companies handle the processing of order confirmations and monitoring of deadlines differently. In some, for example, the need requester takes over monitoring since they know best which products are most important or urgently needed. Others delegate this task to purchasing.

There are significant differences among companies in goods receipt processing. In general, it can be said: the more advanced the digitization in the company, the shorter the processing time – see Figure 4.

Invoice Processing

As Figure 5 shows, the processing time per invoice ranges from 1 to 13 minutes – averaging 4 minutes. Without digital solutions, the effort exceeds 10 minutes per document.

The previous considerations focused on the time required for the individual phases of the order process.

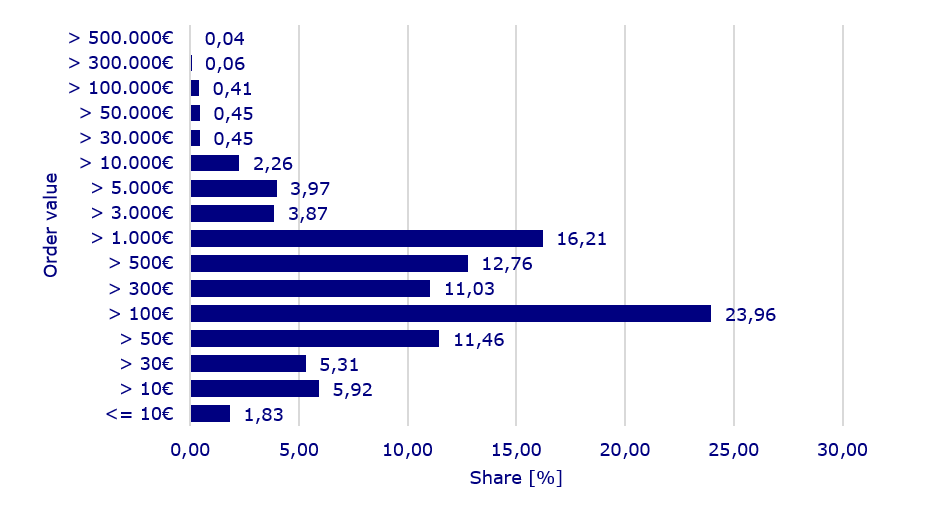

When working with clients on projects, we also examine the value distribution of the orders – Figure 5.

Orders with low order values often make up 30-50% of all orders in a year. The associated workload across the organization can burden staff and distract them from important tasks.

Boost Your Processes into the 21st Century

So far, we have gained an overview of the time required for the individual process phases in companies.

You may wonder why time was used here instead of costs. In our opinion, the time required for an activity is always clear. Experience has shown that it is not easy for companies to determine cost rates for activities across all areas.

The challenge is to find out which activities are meaningful and necessary for your company’s success. Are there activities that individual departments carry out in parallel without knowing that the other department is doing the same? How well-trained are your employees in the processes and systems?

Do you know how long each step takes in your company?

In numerous optimization projects, we have found that an outside perspective is very helpful in identifying blind spots. Together, measures can then be initiated and progress tracked, leading to measurable improvements.

Kloepfel Consulting offers tailored solutions for efficiency, transparency, and sustainability in the supply chain. With experience from hundreds of projects, we are the guide to optimizing and strengthening your activities.

Authors:

Contact:

Kloepfel Group

Christopher Willson

Tel.: 0211 941 984 33 | Mail: rendite@kloepfel-consulting.com