Where engineering meets procurement, unexpected savings emerge

In times of global crises, unstable supply chains, and rising production costs, technical sourcing is becoming a strategic lever for companies. Especially in industrial sectors—ranging from mechanical engineering and automotive suppliers to aerospace—procurement departments are under pressure. They must reduce costs while simultaneously ensuring quality and supply security.

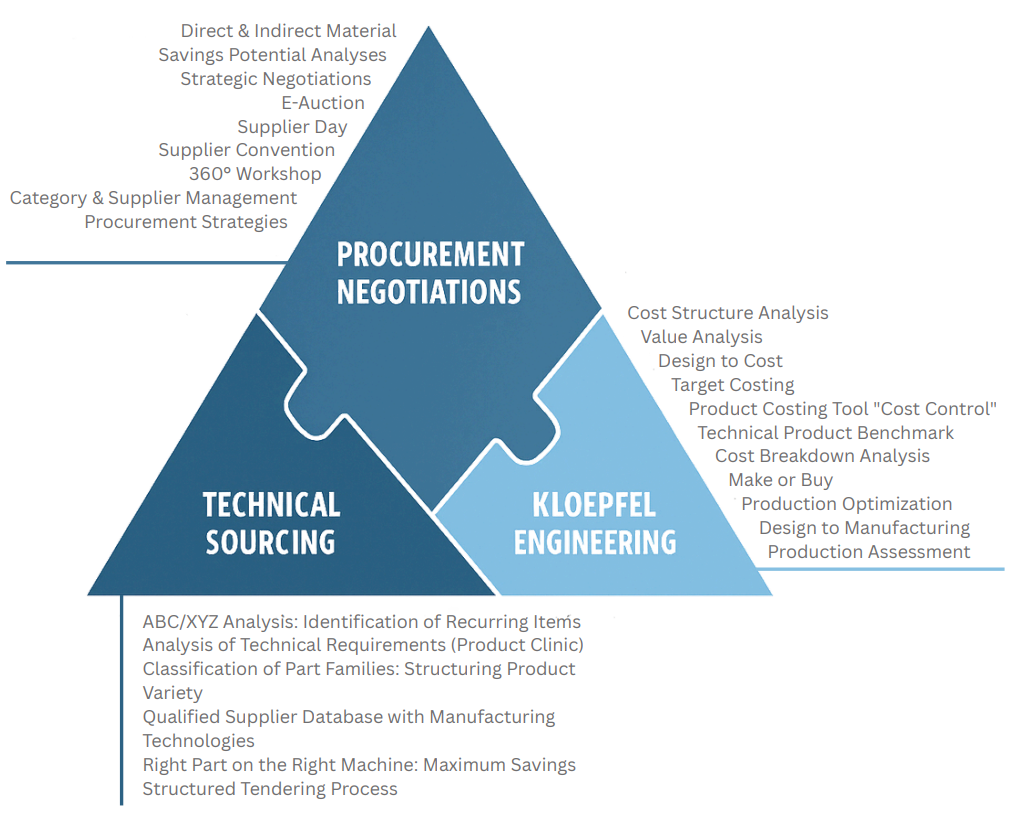

The unique Technical Sourcing approach by KLOEPFEL Consulting offers tangible solutions with measurable savings and a win-win strategy for all stakeholders. KLOEPFEL Consulting has systematically developed this concept and refers to it as the “Success Triangle”:

- Price improvements in strategic procurement

- Cost engineering for analyzing and optimizing technical products

- Technical sourcing to identify the most suitable suppliers

1. Price Improvements: Realize Savings of 3 to 9 Percent

The first step involves KLOEPFEL Consulting’s experts analyzing existing prices and comparing them with benchmarks from their global databases. Through targeted negotiations with both existing and new suppliers, savings of 3–6% on direct costs and 4–9% on indirect costs can be achieved. The focus is not merely on price pressure but on analyzing price structures objectively and renegotiating using solid arguments.

However, this lever alone is often not enough—especially for complex technical products. This is where cost engineering comes into play.

2. Cost Engineering: Identify 20 to 50 Percent Savings in Technical Products

Cost engineering involves an in-depth technical analysis:

How is the product constructed?

What materials and manufacturing steps are used?

Where are hidden or avoidable costs?

Example: A component may be intricately machined, although a more cost-effective casting process would be sufficient. Or a material may be over-specified, when a comparable but more affordable alternative would work just as well.

Such potential is uncovered by KLOEPFEL’s cost engineers, working hand-in-hand with purchasing, development, and production—always in close cooperation with the customer’s technical departments.

And it’s not only the client who benefits. Suppliers also gain from this process, as reducing product costs improves their margins, enabling them to remain profitable even when offering lower prices. The result: a partnership based on technical efficiency.

On average, KLOEPFEL cost engineers identify savings of 20 to 50 percent, especially for complex, multi-step manufactured products.

3. Technical Sourcing: Finding the Right Supplier with the Right Technology

Cost engineering often reveals that a product cannot be manufactured cost-effectively by the current supplier, simply because the required technology or machinery is lacking. This is where technical sourcing becomes essential.

KLOEPFEL’s technical sourcing specialists identify global suppliers that possess the specific manufacturing technologies, machines, and tools needed to produce the required component. Thanks to modern databases and deep technical expertise, they are able to find suppliers who:

- Operate with lower production costs

- Have superior technological capabilities

- And can offer better prices even with the same profit margins

The result: Savings of 12 to 40 percent—with an average of 21.8% in 2024—and a significantly better match between product and production capabilities.

Again, it’s not only the client who benefits. Suppliers can leverage their core competencies and operate profitably- instead of barely staying afloat using inefficient production methods.

Contact

Kloepfel Group

Damir Berberovic

Tel.: 0211 941 984 33 | Mail: rendite@kloepfel-consulting.com